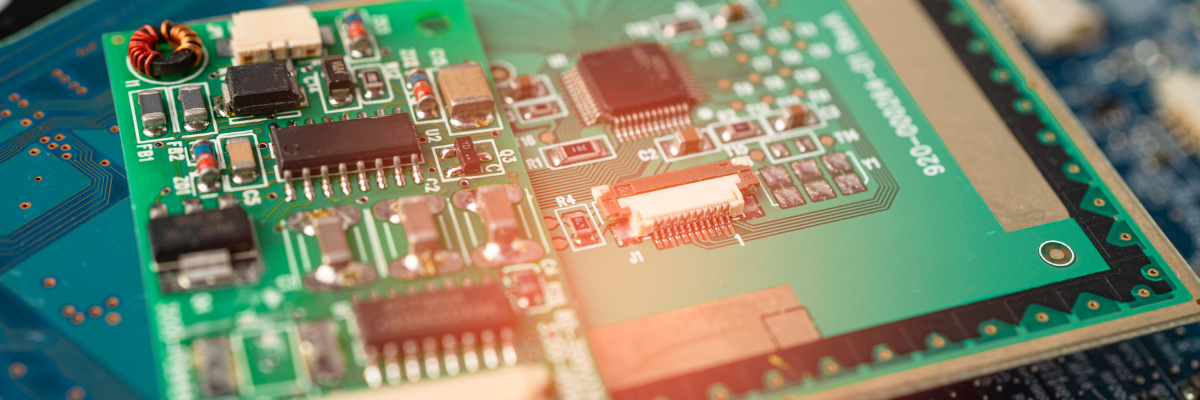

The continual evolution of technology has resulted in faster, and more powerful electronic equipment. These can include LED lights, AV systems, power regulators, and industrial transistors. Such varied applications require a specialized PCB that can help manage power, and ensure product stability. Printed circuit board manufacturers provide the solution with metal core PCBs.

What are Metal Core PCBs?

These PCBs are different from normal circuit boards, as they do not have the general FR4 copper base. Metal Core PCBs (MCPCBs) are designed with a metal core base, which comprises one of three metals – copper, aluminum, or steel alloy. These three metals are chosen for particular reasons.

- Aluminum is capable of transferring and dissipating high levels of heat easily. Also, it is quite economical when considering aspects such as cost, rigidity, and thermal conductivity.

- Copper is well-known for its use in PCBs. It can enhance the performance of the PCB easily.

- Mild and stainless steel are chosen for their rigidity, and low thermal conductivity.

The metal for the base is chosen based on the requirements of a particular application.

The Difference between MCPCBs and FR4 Circuit Boards

Apart from the PCB core, the main component that differentiates MCPCBs from FR4 PCBs is the dielectric material. This is installed in the MCPCB for thermal conductivity. The dielectric material acts as a bridge between the metal backing plate, and the IC components. Also, MCPCBs can be designed with an additional heat sink for heat dissipation. Unlike metal core PCBs, FR4 boards always require a heat sink for heat dissipation. Otherwise, the heat will remain stagnant.

Benefits of Metal Core PCBs

There are three primary benefits of metal PCBs.

- Dimensional Stability: The metal core, and the size of the PCB allows for dimensional stability. Large aluminum PCBs are known to dissipate heat up to 150oC.

- Heat Dissipation: MCPCBs are able to remove heat from all types of ICs. The aluminum base connects the integrated circuits with the heat sink. This ability eliminates the need for multiple surface mounted heat sinks.

- Thermal Expansion: Depending on the metal used, the thermal expansion of MCPCBs will differ slightly. However, both copper and aluminum show good levels of thermal expansion when used as the metal core bases.

These various reasons make metal core PCBs ideal for a variety of industrial and commercial electronic applications. MCPCBs can provide the requisite power, stability, and support to ensure durable application performance.