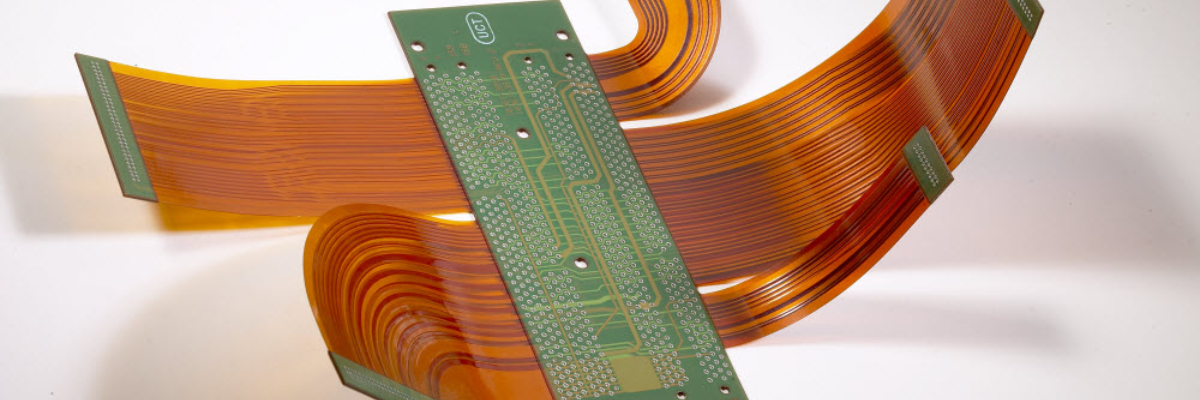

Modern electronics often need circuit boards that bend, fold, or fit into tight spaces without sacrificing reliability. That is where flexible PCBs and semiflex PCBs come in, but they solve design problems in different ways. A flexible PCB is built for repeated or static bending, making it ideal for tight routing and dynamic motion applications. A semiflex PCB, on the other hand, combines rigid board stability with a limited-flex section, allowing controlled bending during assembly while keeping the final structure firm and durable.

This post compares flexible PCBs vs. semiflex PCBs, explains what semiflex PCB technology is, outlines the industry process for semiflex builds, and breaks down benefits and applications to help you select the right approach for your next product.

Semiflex PCBs vs Flexible PCBs: A Quick Comparison

Choosing between semiflex and flexible PCBs can be challenging due to their distinct features. Below is a comparison of their key aspects, which should help you make an informed decision:

| Aspect | Semiflex PCBs | Flexible PCBs |

| Construction | Rigid sections joined by flexible interconnects for selective bending capability. | An entirely flexible substrate allowing continuous bending throughout the board. |

| Durability | Higher structural stability with reinforced rigid areas resisting mechanical stress. | More susceptible to damage without proper reinforcement in high-stress applications. |

| Lead Time | Faster production with conventional manufacturing equipment and standard processes. | Extended manufacturing time due to specialized tooling and material preparation. |

| Testing | Conventional electrical testing methods with standard fixturing approaches. | Specialized test fixtures needed to accommodate flexible board geometry. |

| Application | Ideal for devices needing localized flexibility with stable mounting areas. | Best suited for applications requiring continuous flexing or folding operations. |

| Design Complexity | Simpler layout with defined rigid and flexible zones, reducing design iterations. | Requires careful consideration of bend radii throughout the entire circuit design. |

Key Advantages of Semiflex PCBs

Semiflex PCBs offer several design and manufacturing advantages that address common mechanical, assembly, and space-related challenges. A few of them include:

- Structural Stability with Limited Flexibility: Semiflex PCBs combine rigid FR4 sections with flexible bend zones, allowing controlled bending during assembly while maintaining long-term mechanical stability. This design revents stress fractures common in repeatedly flexed circuits.

- Reduced Connectors and Assembly Complexity: By integrating rigid and flexible sections into one board, semiflex PCBs eliminate connectors, and significantly reduce the number of solder joints. This improves signal reliability while simplifying assembly processes, lowering manufacturing costs and increasing overall product robustness.

- Space Optimization in Compact Designs: Semiflex PCBs support three-dimensional layouts, enabling tighter packaging of components, minimizing board area, and making them ideal for space-constrained devices where rigid boards cannot meet enclosure limitations.

- Semiflex PCBs support three-dimensional layouts that allow tighter packaging of components and more efficient use of available space. This helps minimize board area and makes them ideal for compact devices where rigid boards cannot meet enclosure limitations.

- Improved Reliability Over Full Flex Circuits: Because semiflex PCBs are bent only once during installation, they experience less mechanical fatigue, offering higher durability and longer service life compared to dynamic flexible PCBs in static applications.

Key Advantages of Flexible PCBs

The main advantages of flexible PCBs for modern electronic assemblies are as follows:

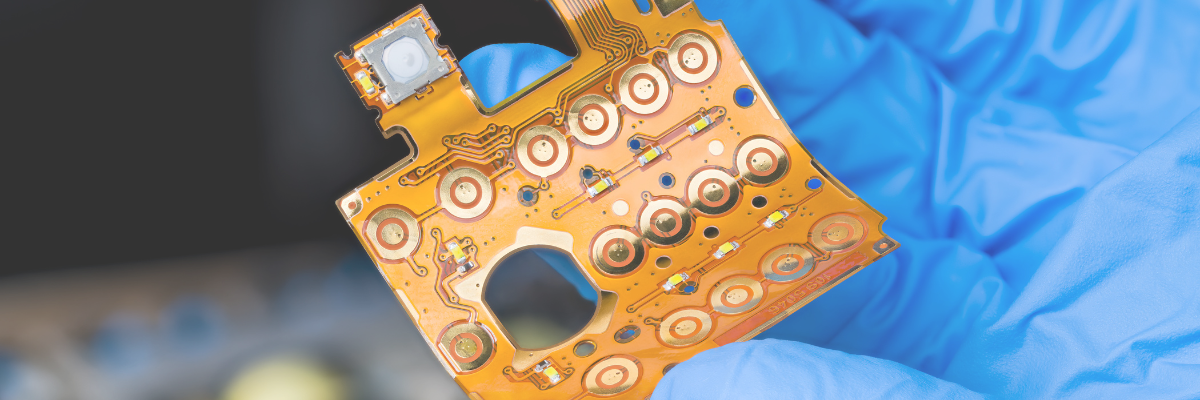

- Continuous Flexing and Dynamic Movement Support: Flexible PCBs are engineered to withstand repeated bending, twisting, and folding, making them ideal for applications involving motion, such as wearables, hinges, robotics, and dynamic cable-replacement scenarios.

- Ultra-Thin and Lightweight Construction: Built on polyimide substrates, flexible PCBs significantly reduce weight and thickness compared to rigid boards. This design supports compact product designs while improving portability, thermal performance, and overall mechanical adaptability.

- Enhanced Design Freedom and Routing Efficiency: Flexible PCBs allow complex routing through tight spaces and irregular shapes, enabling creative product layouts, fewer interconnects, and improved signal integrity in densely packed electronic assemblies.

- Improved Vibration and Shock Resistance: The inherent flexibility of flex PCBs absorbs mechanical shock and vibration better than rigid boards, enhancing reliability in automotive, aerospace, medical, and industrial environments with constant mechanical stress.

Industry-Wise Applications of Semiflex PCBs

Semiflex PCBs are used across many industries where structural stability and limited flexibility are required. A few of the key application areas include:

- Consumer Electronics: Used in smartphones, wearables, and cameras, semiflex PCBs enable compact folding zones with rigid stability, reducing connectors, improving shock resistance, and supporting high-density component placement under constrained spaces.

- Medical Devices: Medical devices rely on semiflex PCBs for reliable interconnections in imaging probes, implants, and monitors. Their combination of bendable routing and rigid accuracy supports biocompatibility, durability, sterilization processes, and regulatory compliance requirements.

- Automotive Electronics: Automotive electronics use semiflex PCBs in dashboards, sensors, and control modules. These boards tolerate vibration, heat, and mechanical stress while maintaining signal integrity, space efficiency, and long-term reliability in harsh operating environments.

- Industrial and Aerospace Systems: Industrial and aerospace systems use semiflex PCBs in control units, sensor modules, and compact avionics assemblies where space is limited and reliability is critical. Their ability to reduce wiring complexity while withstanding extreme temperatures, vibration, and repeated motion supports dependable performance in mission-critical environments.

Industry-wise Applications of Flexible PCBs

Flexible PCBs support a broad range of industry needs, and some of the key applications include:

- Consumer Electronics: Consumer electronics depend on flexible PCBs for dynamic bending, lightweight construction, and ultra-thin profiles in foldable phones, laptops, and displays. Their capabilities support innovative form factors, reduced weight, and improved product portability.

- Healthcare and Wearable Technology: Healthcare and wearable technology rely on flexible PCBs to support compact, body-conforming designs used in biosensors, monitoring patches, and wearable devices. Their ability to bend with movement while maintaining stable signal transmission makes them well suited for continuous patient monitoring and long-term daily use.

- Automotive and EV Systems: Automotive manufacturers integrate flexible PCBs into lighting systems, battery connections, and infotainment units. These boards support three-dimensional routing, resist vibration, optimize space, and simplify wiring within increasingly electrified vehicle architectures.

- Aerospace, Defense and Automation: Aerospace, defense, and industrial automation applications use flexible PCBs in avionics modules, control systems, robotic assemblies, and sensor networks where weight reduction and reliable signal routing are critical. Their ability to operate through continuous motion, tight installation spaces, and harsh environmental conditions supports consistent performance in mission-critical systems.

Partner with Rigiflex Technology for the Right Flex PCB Solution

Choosing between semiflex PCBs and flexible PCBs depends on how much movement, durability, and space optimization your product requires. Rigiflex Technology helps you evaluate both technologies, aligning design intent with performance, reliability, and cost efficiency.

Our experts support you from design consultation through production, ensuring the ideal PCB solution for your application. Contact us at (714) 688-1500 or email pcboards@rigiflex.com to discuss your next project.