The use of electronic and electromechanical systems and equipment has become integral to residential, commercial, and industrial facilities. These systems revolutionized several industrial processes and the way certain tasks are performed. Similarly, they have also changed how we use various electronic gadgets in our daily lives, smart devices, IoT, and so on. These systems’ performance and shelf life depend on different circuit boards over which elements are assembled. Printed circuit boards (PCBs) and breadboards are the most popular mediums or substrates for circuit designs today. They play a crucial role in bringing life into electronic devices. Are you intrigued to know more about them? This post offers a comparative account of PCB vs breadboard, which will help you choose the right one based on your requirement. So, stay tuned.

Get Introduced to PCBs and Breadboards in Detail

Before discussing PCB vs breadboard, it is essential to know what they are. Here is a quick introduction to PCBs and breadboards.

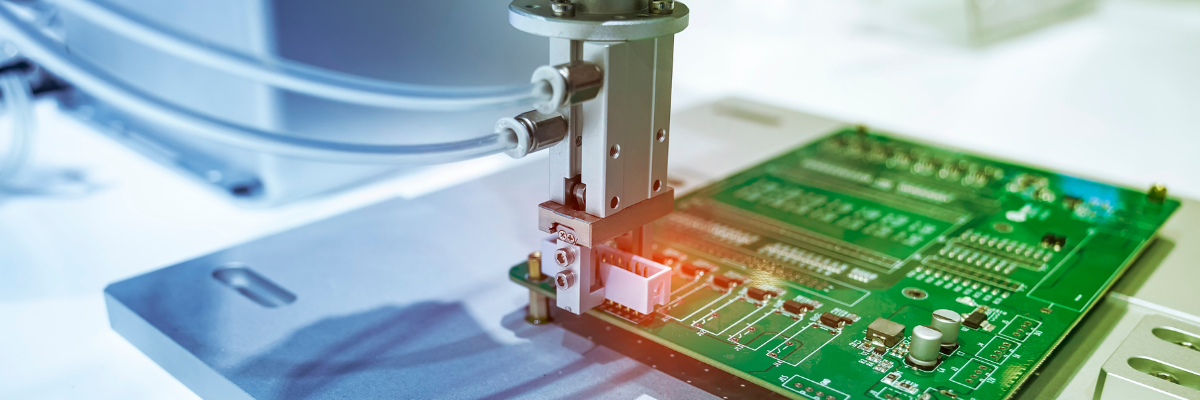

- PCBs: PCBs are an essential component of modern electronics. They offer a platform for assembling and connecting electronic components to create functional circuits. It is a flat board made using non-conductive materials and a copper foil laminated onto it. The copper layer creates a conductive path called traces forming interconnections between the components. PCBs offer several advantages: precision, efficiency, space efficiency, scalability, and more.

- Breadboards: These are used by students, newbies, and hobbyists during the initial circuit designing stage to explore and learn about electronics. They are plastic boards with a grid of interconnected holes or sockets. Breadboards are easy to use and don’t require any specialized tool. This makes them accessible and ideal for rapid prototyping, educational purpose, and circuit experimentation.

PCB vs Breadboard – Know the Real Difference

Here are some pointers that differentiate PCBs and breadboards.

- Design: PCBs are a permanent solution for circuit designing available today. The electronic components are soldered once the circuit boards are designed and manufactured, creating a reliable connection. On the other hand, breadboards are a temporary platform for circuit prototyping. Here, components are placed onto unsoldered boards, allowing easy reconfiguration and experimentation.

- Circuit Complexity: PCBs are widely preferred for complex circuitry, precise placement of components, signal routing, and so on. In contrast, breadboards are best suited for simple and moderately complex circuits. Although they can accommodate components, their loose connection and limited interconnectivity may introduce severe issues, such as signal integrity.

- Component Placement: PCBs offer a precise component placement approach during the designing phase. Components are soldered in an accurate location, ensuring reliable electrical connection. Conversely, breadboards prefer flexible component placement.

- Durability: PCBs are made of high-quality and robust materials with several layers and coatings. They have a long operating life and are designed to withstand challenging environmental factors, such as moisture, temperature variations, and so on. Breadboards are not intended for long-term use. Their electrical connections can loosen with regular usage, which may affect the stability aspect.

- Size and Compactness: PCBs are designed to be compact, making them suitable for complex, miniature, and performance-driven applications. Breadboards are not optimized for compact designs.

- Scalability and Mass Production: Unlike breadboards, PCBs can be mass produced. Once done with the design, they can be manufactured in large quantities, upgraded, and reworked upon. This offers cost advantages for industrial and commercial production. Breadboards are primarily used for prototyping or on a practical level.

PCBs and breadboards have their own sets of advantages and limitations. PCBs provide durability and precision, which makes them ideal for production-ready systems, while breadboards are suitable for prototyping and experimentation. With the aforementioned pointers, you can easily make the right choice. It is always good to consult experienced industry players like Rigiflex Technology if you require further clarity. The company is a renowned PCB manufacturer and assembly service provider in the USA. With years of experience and skilled employees, the company specializes in designing and building PCB assemblies for several applications and providing custom solutions. Contact them today to discuss your application requirement.