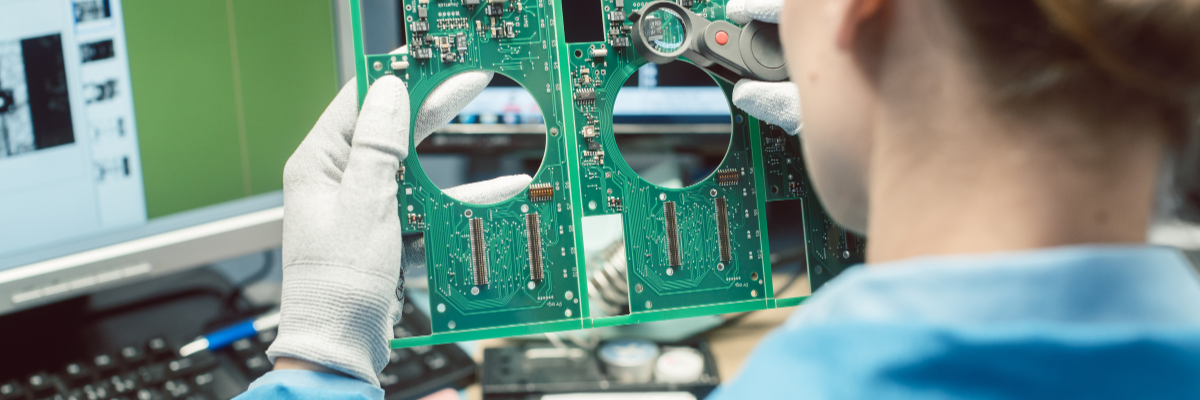

Printed circuit board assemblies being a crucial part of most devices and machines need to be thoroughly tested in terms of structural as well as functional accuracy. There are various types of testing techniques used at each step of manufacturing of fabricating blank boards as well as when assembling them. X-ray inspection is one of the testing techniques commonly used. This is also called Automated X-ray Inspection (AXI). The x-rays scan the board to identify hidden solder joints, wiring, components, and so on. This post discusses the details of x-ray inspection as a testing technique for PCBs and assemblies, its advancements over the years, and its use in testing of modern devices.

Overview of X-ray Inspection Technique for PCBAs

X-ray testing based tools or devices are used to scan the assembled boards for optically hidden details and issues in circuit, open wires, wrongly placed components, solders, and so on. These devices comprise a tube with x-ray generator, projection microscope, a platform to move the sample at various angles, and an x-ray detector that converts it into an image for visual presentation. These systems are available in 2D and 3D configurations. The x-rays penetrate far deep into the board. This penetration factor is a big advantage that has surged the demand of this technique among PCB manufacturers. The materials used in circuit boards absorb the x-rays in varied proportions depending on their atomic weight, density, and so on. Heavy materials absorb more x-rays than lighter ones and hence can be easily imaged. Clarity of images has played a huge role in driving the growth of this technique. A good testing system must have the oblique angle inspection as well as cross sectional images feature aside from the ability to inspect ball grid arrays and CSP. Nowadays, it is used to check PCB assemblies in mission critical applications such as aerospace, defense, medical, and so on.

Advancements in X-ray Inspection Technique

There is a huge scope for non-destructive testing techniques and they are preferred by manufacturers as they test the board while it is operational and in a live environment. This is because it eliminates downtime, mechanical cross sections, and wastage of resources. Also, there is a huge demand for automated inspection techniques. Both of these requirements are met in x-ray testing technique apart from the level of penetration and image clarity. This technique has evolved over the years. There has been much research done to develop advanced versions of x-ray inspection systems. New algorithms are being developed to scan complex board designs. They offer high definition images, increased testing speed, and significantly enhanced defect identification. This is aside from the automation feature as it already exists in this testing technique. Here are some pointers regarding advancements in x-ray inspection systems.

- Advanced systems developed over the last few years offer extremely high and sub-micron resolution and a huge bandwidth.

- Their x-ray generator tube is powerful and the detectors can now have an image intensifier feature than enables amazing image clarity around 10-12 megapixels.

- It enables NDT or non-destructive testing by producing e-cross sections where the plane angle can be changed to examine open wires, shorts, and so on.

- 3D µCT x-ray testing systems developed enable the board or sample to be suspended between the detector and tube. Hence, virtual cross sectioning and slicing becomes easy.

- Since the process is automated, there is an in-built software which identifies, pitches, bumps, BGA diameters, and so on of the sample boards and compares all of these with reference values given earlier.

If you are looking for reliable PCB assembly services provider for incorporating PCBA in your product, ensure you partner with an experienced and certified player who has dealt with PCBA requirements of clients across sectors. Rigiflex offers customized and end-to-end PCBA solutions and they implement stringent testing techniques including x-ray based testing to check each detail of their boards. They have been in the market for more than two decades.