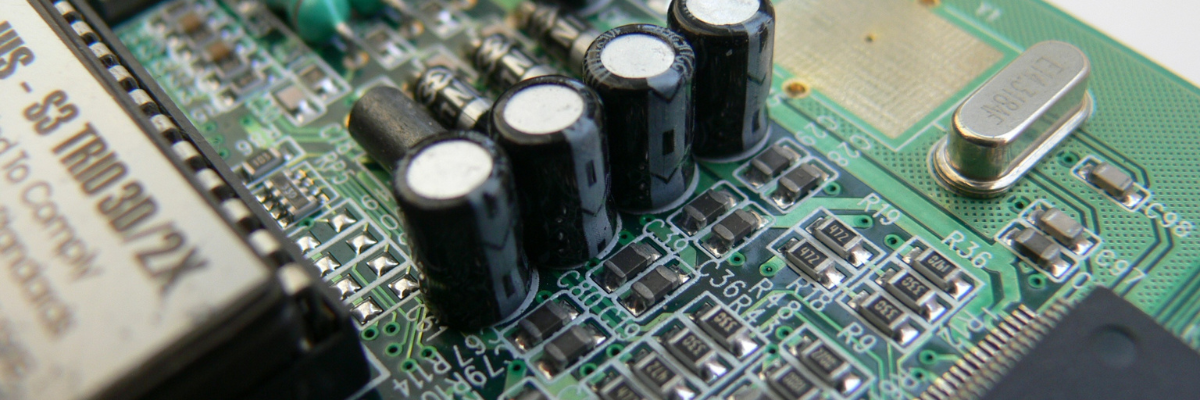

As the global demand for clean and sustainable energy continues to rise, renewable energy systems are at the forefront of technological advancement. Whether it is solar panels, wind turbines, or energy storage systems, the one component that drives the functionality of these systems is the printed circuit board (PCB). These PCBs control, monitor, and regulate the performance of complex systems. However, designing and manufacturing the PCBs for renewable energy applications comes with its own set of challenges. This post discusses these challenges and innovations in PCBs in renewable energy systems.

Key Challenges in PCB Design for Renewable Energy

The increasing sophistication of renewable technologies has led to a demand for more powerful, compact, and reliable PCBs capable of withstanding extreme conditions. However, developing PCBs that can withstand the rigorous demands of renewable environments requires overcoming several key engineering challenges, including:

- Environmental Stress: The renewable systems are frequently deployed in outdoor or remote environments exposed to moisture, dust, temperature extremes, and UV radiation. The printed circuit boards must be designed to withstand challenging environmental conditions to ensure reliable operation over an extended period.

- Thermal Management: Renewable systems, especially solar inverters and wind converters, generate significant heat during operation. The solar panel heat may be exposed to heat between 140 and 185 degrees Fahrenheit, where extreme temperature combined with environment elements can make traditional PCB designs fail, potentially leading to failure or reduced lifespan. Thus, designers need to plan for thermal management by integrating thermal vias, heat sinks, and high-temperature substrates like polyimide or ceramic-based materials.

- Material Selection: The material cost for the printed circuit board used in renewable energy applications is high. They may be even higher for large scale deployments. Choosing the right material is crucial for ensuring the durability and reliability in harsh environments. Some traditional PCB materials can be environmentally harmful, requiring the use of sustainable materials.

- High Power Handling: Renewable systems often operate at high voltages and currents. Thus, the printed circuit boards used in these settings must feature larger copper traces and thicker layers to carry the current load without excessive resistance or overheating. Designing high-power PCBs requires a delicate balance between efficiency and size.

- Electromagnetic Interference (EMI): EMI becomes a critical issue when multiple high-speed components are operating in proximity. When a PCB is integrated in an application operated in high-power and high-noise environment, it can struggle to maintain its integrity. The printed circuit boards must be designed with proper grounding, shielding, and spacing strategies to minimize interference, ensuring the system’s communication and control integrity remains intact.

Innovations Driving PCB Performance in Renewable Energy

To overcome these challenges, PCB manufacturers like Rigiflex are embracing innovation and precision engineering.

-

- Advanced Materials: The move from traditional FR-4 to high-performance materials like polyimide, PTFE, and metal-core PCBs is gaining traction. These materials offer better thermal resistance, electrical performance, and mechanical durability essential for long-term field deployment in solar and wind applications.

- Flexible and Rigid-Flex PCBs: Compact designs and weight reduction are crucial in applications like compact inverters or portable battery packs. Rigid flex printed circuit boards combine the best of flexible and rigid boards. They assure the durability of rigid board and flexibility of flexible boards, providing versatility for various renewable energy applications. Flexible and rigid-flex PCBs enable 3D design possibilities, reducing connectors, improving signal integrity, and enhancing mechanical strength.

- Thick Copper PCBs: Heavy copper PCBs can handle high rates of current, providing strong connection points and resisting temperature extremes for a long time. These PCBs find application in renewable energy applications, such as solar trackers, wind turbines, and so on.

- High-Density Interconnect (HDI) Technology: As renewable systems become smarter, the density of components on a PCB has increased. HDI PCBs, with their microvias, fine traces, and multi-layer architecture, allow engineers to pack more functionality into smaller footprints without compromising performance.

- Surface Mount Technology: Many renewable energy machines feature sensitive electronic components, which are often challenging to install without damage. The surface mount techniques allow printed circuit board assembly services to place these components without damaging them.

- Smart Monitoring and Embedded Sensors: Modern PCBs can integrate sensors directly on the board to monitor temperature, current, humidity, and more. These embedded monitoring systems help preempt failures, reduce downtime, and enhance energy efficiency—vital metrics in the renewable sector.

The Rigiflex Advantage: Precision-Engineered PCBs for a Sustainable Future

The team at Rigiflex understands that the future of renewable energy depends on innovation, reliability, and uncompromising quality. Whether you’re designing next-generation solar inverters or robust battery management systems, Rigiflex delivers the PCB performance and reliability your application demands. The company offers customized solutions tailored to the demanding requirements of solar, wind, and energy storage applications. From thermal-efficient multilayer PCBs to durable rigid-flex assemblies, their expertise ensures your renewable energy system performs optimally in every condition. Looking for a PCB solution built to thrive in the renewable energy revolution? Get in touch with Rigiflex today and discover how our cutting-edge PCBs can power your green innovations. Contact us now to request a quote or speak to an expert.