In 2000s, wearable medical devices transitioned from futuristic concepts to everyday health companions. From smartwatches tracking heart rates to continuous glucose monitors helping manage diabetes, these devices are transforming personal healthcare. But what powers these tiny, life-enhancing devices? PCBs! These boards connect and support the complex electronic components needed for data collection, processing, and wireless communication. As the demand for more comfortable medical wearables has grown, so too has the need for innovative PCB technology that can keep up with these advancements. This post explores the evolution of PCBs, from rigid boards used in early designs to the flexible and biocompatible circuits found in today’s smart wearables. It also discusses the key role of PCBs in many wearable devices of today.

Timeline: The Evolution of PCBs in Wearables

The evolution of PCBs in wearable medical devices has followed the rapid pace of innovation in both electronics and healthcare. Here’s a look at the evolutionary timeline of PCBs in wearable medical technology:

- In the 1980s and 1990s, the earliest wearable medical technologies relied heavily on rigid PCBs made from traditional fiberglass materials. These boards were large, inflexible, and not suited for direct contact with the human body, but they powered the first generation of portable diagnostic tools like Holter monitors and handheld ECG devices.

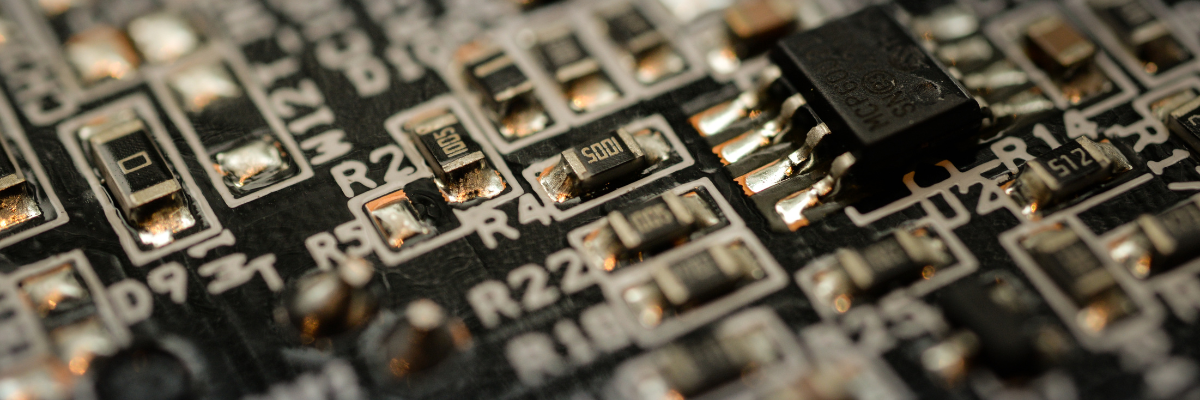

- By the 2000s, miniaturization began to reshape PCB design. Smaller, more efficient single and double-layer PCBs were developed, leading to more compact wearable health devices such as early fitness trackers and wireless digital thermometers. The adoption of Surface Mount Technology (SMT) allowed components to be placed directly onto the surface of the board, significantly reducing space requirements.

- The 2010s introduced a breakthrough with the widespread use of flexible and rigid-flex PCBs. Using materials like polyimide, these boards could bend and conform to different shapes, making them ideal for wearable applications. Devices such as smartwatches with ECG capabilities, insulin pumps, and wearable ECG patches benefited from this new generation of circuits.

- In the 2020s and beyond, the industry has seen the rise of smart, stretchable, and bio-integrated circuits. These advanced PCBs are not only flexible but also capable of stretching and molding with the body’s movements. Stretchable electronics, ultra-thin biosensors, and printed PCBs now enable real-time health monitoring with minimal discomfort.

The Role of PCBs in Wearable Medical Devices

Printed Circuit Boards (PCBs) are the foundation of all electronic devices, and their role in medical wearables is especially critical.

- Power precision in health monitoring: Wearable medical devices need to be accurate, real-time and reliable. PCBs make this possible by integrating various components. This allows the device to track metrics such as heart rate and ECG, blood pressure, blood temperature and glucose level.

- Support miniaturization and comfort: For medical wearables to be comfortable and non-invasive, they must be lightweight, compact and flexible. Flexible PCBs allow engineers to pack more functionality into smaller footprints making devices wearable on the wrist, skin or embedded in clothing.

- Ensure device reliability and safety: In healthcare, reliability isn’t optional, it’s life-critical. PCBs in medical devices are designed to meet stringent industry standards and certifications. These designs must withstand constant movement, temperature fluctuations, long-term skin contact and exposure to sweat or moisture.

- Enable connectivity and data transmission: Many wearable devices rely on Bluetooth, Wi-Fi, or NFC to communicate with smartphones or cloud platforms. PCBs support this connectivity by incorporating radio frequency (RF) components and antennas, helping to transmit patient data securely to health apps or medical professionals.

The evolution of PCBs in wearable medical devices reflects the extraordinary progress in healthcare technology. What began with rigid, bulky boards has transformed into a world of ultra-flexible, lightweight, and high-performance circuits that seamlessly integrate with the human body. If you are looking to take your medical or wearable device to the next level, partnering with an experienced PCB manufacturer is key. Rigiflex Technology Inc. specializes in rigid-flex and flexible PCB solutions tailored for wearable medical devices. Explore their full PCB capabilities and request your personalized quote today at Rigiflex.