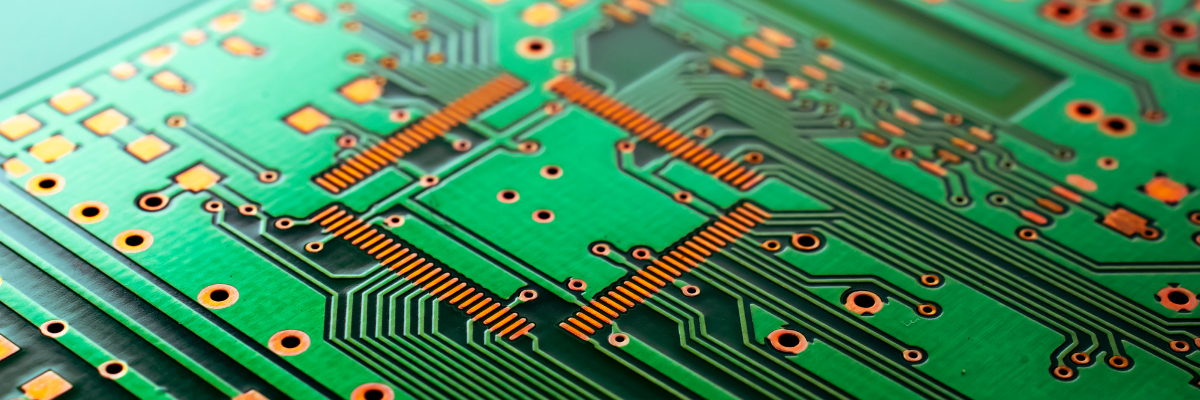

A printed circuit board, popularly known as PCB, is a module featuring several interconnected components that are aligned to ensure a current flow through devices wherein they are installed. PCBs have been an integral part of several electronic devices ranging from radios to computer systems to radar systems.

Printed circuit boards are mainly distinguished into three types – single-sided, double-sided, or multilayered depending on their construction. These circuit boards get their name from component positioning on a single side, double side, or across multiple layers. After reading this, are you intrigued to know about printed circuit board materials for fabrication?

An Elaborate Overview of Printed Circuit Board Materials for Fabrication

The base or foundation of the printed circuit board comprises a laminate and the substrate. The substrate is basically a non-conductive material, which is often chosen based on their dielectric constant dk. Laminates are used with substrates, and they provide the surface material. Sometimes, laminates are used as core materials. Electronic components are positioned on the substrate and then soldered to the circuits that are interconnected. There are contact fingers included on substrate edges, which serve as connectors to other PCBs or other external devices.

Substrates: These are dielectric composite structures featuring epoxy resin and glass or paper woven material. These substrates may be sometimes supplemented with materials like ceramic to improve their dielectrics constant. Sometimes unwoven paper or glass weave is also used. Substrates are usually manufactured to meet specific properties of applications. There are various types of substrates used for PCB fabrication. They are basically distinguished as – hard/rigid, soft/flexible, flex-rigid, and FR4 – based on their construction.

FR4: This is perhaps one of the most popular printed circuit board materials used for fabrication, owing to its variety, reliability, and above all affordability. FR4 material is basically fiberglass-epoxy laminate, which is flame-resistant, and possesses excellent electrical insulation properties. In addition to this, FR4 offers several advantages over other substrate materials such as excellent resistance to weight ratio. The material does not absorb moisture and excellent mechanical strength at all times. It can also retain its insulation properties in humid and dry environments.

Unlike the common perception FR4 is not a single material, but a common grade of materials that are designated by NEMA, which is a US trade organization. FR in FR4 stands for fire retardant, and it suggests that the material is UL94VO compliant. FR4 is available in various grades. They are:

- Standard: The material has heat resistance up to 140°C to 150°C, and hence this is a common choice of FR4 substrate for regular applications.

- High Transition Temperature: As the name suggests, this FR4 variant has a high glass transition temperature up to 1180°C. These substrates are compatible with lead-free reflow technologies.

- Halogen-free: These FR4 variants are compatible with lead-free reflow technology.

- High CTI FR4: FR4 materials of this type have a high comparative tracking index, which may sometimes be as high as 600 Volts.

- With No Laminated Copper: FR4 substrates of this type are ideal for board supports and insulation plates.

Although FR4 substrates have been popular for cost and mechanical advantages offered by them, they are not recommended for applications involving RF/microwave frequencies. The next topic discusses a few more PCB substrates in use today.

Substrates are the basic building blocks of printed circuit boards and they play a key role in assuring their integrity. So, you cannot afford to go wrong with them. FR4 is the most common PCB substrate used today. The benefits of the same were covered in the previous post. However, this post introduces you to a few more material and their typical advantages in different applications.

A Focus on Important Types of Substrates Used to Build PCBs

As known, PCBs are distinguished into three types – rigid, rigid-flex, and flexible. The substrate is a major governing factor across all these types. The following are a few popular types of substrates used in these PCBs.

Hard Rigid Substrates: As the name suggests, these substrates are sturdy and they are used to maintain the shape of the PCB. Most of these substrates have a ceramic base, which improves their rigidity. The following are a few popular hard rigid substrates used for construction:

- Aluminum: This material has strong thermal dielectric properties and expands slowly. Aluminum also assures high-frequency performance, and can easily withstand temperatures up to 350ºC.

- Aluminum Nitride: This material possesses its high thermal conductivity. It is also known for high thermal strengths and low expansion. This is widely used as a package.

- Beryllium Oxide: This material possesses high thermal conductivity, and has low expansion like others on this list. However, this is one of the rarely used printed circuit board materials for fabrication, owing to several disadvantages associated with its machining.

Flexible Substrates: These substrates can be easily bent, folded, or wrapped into the desired forms, without affecting the flow of current. Over the years, various flexible substrates have gained popularity as printed circuit board materials of fabrication, owing to several benefits that they offer. The following are a few popular ones among them:

- Polytetrafluoroethylene (PTFE): This material is known for various beneficial mechanical properties such as low dissipation factor and temperature stability. Teflon is one of the most popular PTFE materials available for consideration and it was developed by Chemours.

- Polyimide: Commonly abbreviated as PI, polyimide is a name for imide polymers that offer a blend of desirable mechanical properties such as excellent thermal stability, good thermal resistance, good electrical properties, and excellent chemical resistance. Kapton developed by DuPont is one of the most popular flexible substrates in use today.

- PEEK: This is a polyether ether ketone material, which is valued for its excellent mechanical properties such as resistance to chemicals, temperature, and extreme radiation.

Flex-Rigid Substrates: They are the combination of flexible and rigid substrates. For instance, a PCB may comprise multiple layers of polyimide, which are attached to a ceramic rigid layer. PCBs made of this material are widely used in mission-critical applications across medical, aerospace and aviation, and military sectors, where they may have to endure high temperatures or demanding conditions.

The choice of the right substrate may depend on several application requirements. The post above gives you a brief idea of different substrate materials; however, the PCB manufacturer that you choose to work with may not be dealing with all of these. So, after understanding the typical benefits of each of these substrates, you need to check with them. If you are working with an experienced PCB manufacturer like Rigiflex, you get assistance in choosing the right material. The company has been working with a variety of substrates, and the team has a fair understanding of their utility across applications.