RF and Microwave PCBs have been around for several years and are most commonly used in the electronics industry. They are immensely popular and designed to operate on signals in the megahertz to gigahertz frequency ranges. When it comes to networking and communication applications, these PCBs are ideal. There are many reasons why PCB manufacturers suggest RF and Microwave boards for networking applications. Would you like to know what are they? This post discusses the same.

General Introduction to RF and Microwave PCBs

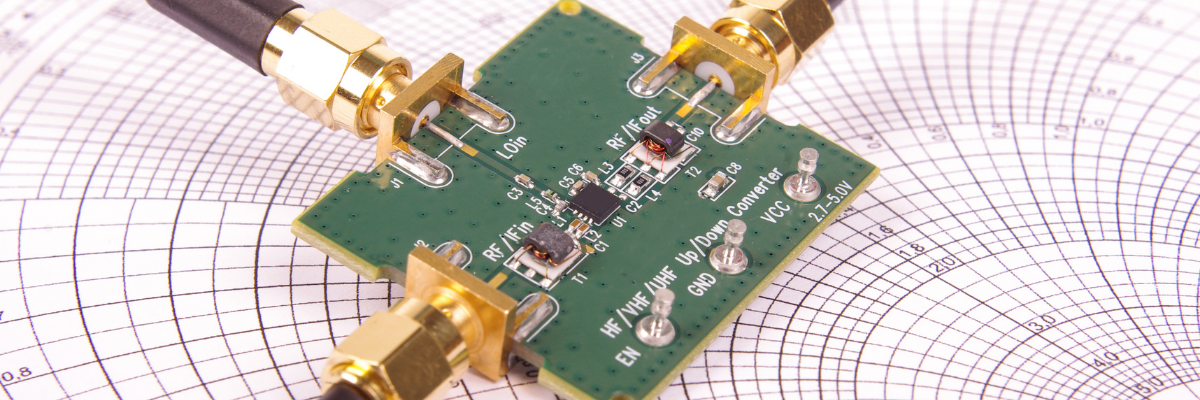

Generally, RF and microwave boards are designed for applications in the medium to high-frequency ranges or for the applications above 100 MHz. Designing of these circuit boards becomes difficult due to reasons varying from the sensitivity of signals to managing the difficulties in managing the thermal heat transfer properties. However, these difficulties don’t diminish their importance. The utilization of materials with properties such as low dielectric constant, high Coefficient of Thermal Expansion (CTE), and low loss tangent has helped ease the construction. PCB materials regularly used for the construction of RF and microwave PCBs are Ceramic filled hydrocarbon, PTFE with woven or micro glass fibers, FEP, LCP, Rogers RO laminates, High-Performance FR-4, etc.

Different Benefits of RF and Microwave PCBs

RF and Microwave PCBs offer several beneficial advantages. So, let’s have look at them one by one.

-

- The use of low CTE materials helps the PCB structure to stay stable in high-temperature environments. Also, these materials enable the easy alignment of multiple layers.

- A PCB engineer can easily align multiple board layers in a complex structure because of the use of low CTE materials.

- The assembly costs of the RF and microwave PCBs can be lowered through the multilayer board stack-up structure. This structure also contributes to the optimal performance of PCBs.

- The stable Er and low loss tangent help transmit the high-frequency signals through these PCB boards at fast rates. Also, the impedance is low during this transfer.

- A PCB engineer can effectively position the fine pitch components onto the board, which helps achieve complex designs.

Thus, these several advantages make RF and Microwave PCBs ideal for various applications including wireless transmission and other computer networking systems. If you are looking to invest in high-quality boards, which will allow transmitting high-frequency signals then you should always contact reputed manufacturer like Rigiflex Technology, Inc. The company is known for manufacturing circuit boards for precise functioning. Moreover, highly skilled experts will help to select the appropriate circuit boards as per your requirements.