Fast turn PCB manufacturing is a process where the manufacturer completes the assembling of printed circuit boards (PCBs) in a quick turnaround time to meet the demands of the marketplace. This process is traditionally and most commonly used for prototype PCBs and low-volume production. The PCBs under this category are designed, fabricated, assembled, and tested in an extremely short duration, with a turnaround time of 24 hours to 7 days, considering the design complexity. This process has become increasingly popular in the electronics industry as companies seek to accelerate their product development cycles and bring their innovative designs to market more quickly. Would you like to know more about fast turn PCB production, if yes then the post is for you.

Why Should You opt for Fast Turn PCB Manufacturing Services?

This process offers numerous benefits for businesses trying to streamline their manufacturing processes, reduce costs, and enhance their efficiency. Below are a few major advantages of opting for fast turn PCB manufacturing:

- Allow Products to Market Fast: The fast turn PCB manufacturing utilizes advanced technologies and optimized workflows that make it possible to manufacture PCBs with shorter lead times and greater degrees of accuracy. This calls for optimizing every action regarding the process, from design to assembly to inspection, to ensure each board meets the highest quality standards and is delivered effectively. This can be particularly ideal for companies seeking to quickly introduce a new product or fulfill unexpected demand.

- Cost Savings: The implementation of quick-turn PCB manufacturing offers cost-saving benefits by streamlining the traditional production procedures associated with PCB manufacturing. By eliminating unnecessary steps in the process, expenses can be minimized to a great extent.

- Improved Efficiency: As said before, fast turn PCB manufacturing utilizes the advanced production technologies and streamlined workflows, which can help to improve overall efficiency. With shorter lead times and fewer steps in the production process, companies can minimize the failure rates and improve their bottom line.

- Optimum Quality: Companies can enhance the quality of their products by opting for fast turn PCB manufacturing services. With the utilization of advanced manufacturing techniques and state-of-the-art equipment, PCB manufacturers can achieve exceptional precision, resulting in higher-quality outcomes while handling fast turn PCB production. As a result, customers can expect more dependable and high-performing products.

Steps Involved in Fast Turn PCB Manufacturing

The process of fast turn PCB production involves several steps, as listed below:

- Design: In this phase, a designer will create a PCB layout/design based on the specifications provided by the client. This includes determining the size, number of solder masks needed, other pieces of component notation and the number of copper layers needed for the PCB.

- Sending the PCB design in Gerber File Format: Once the PCB design has been completed, the next step is sending the file to the manufacturer in a Gerber file format. The Gerber format serves as the industry standard for PCB design files and includes comprehensive information that enables the manufacturer to produce the PCB accurately. By adhering to this protocol, you can ensure a seamless transition from design to manufacturing.

- Material selection: The above step follows the selection and procuring of appropriate materials based on the requirements of the project. This includes the substrate, copper, and any additional layers or coatings.

- PCB Fabrication: The actual production process of fast turn PCBs begins at this stage. It involves various steps, including drilling, plating, and etching. Using the Gerber files provided, the manufacturer meticulously creates the different layers of the PCB.

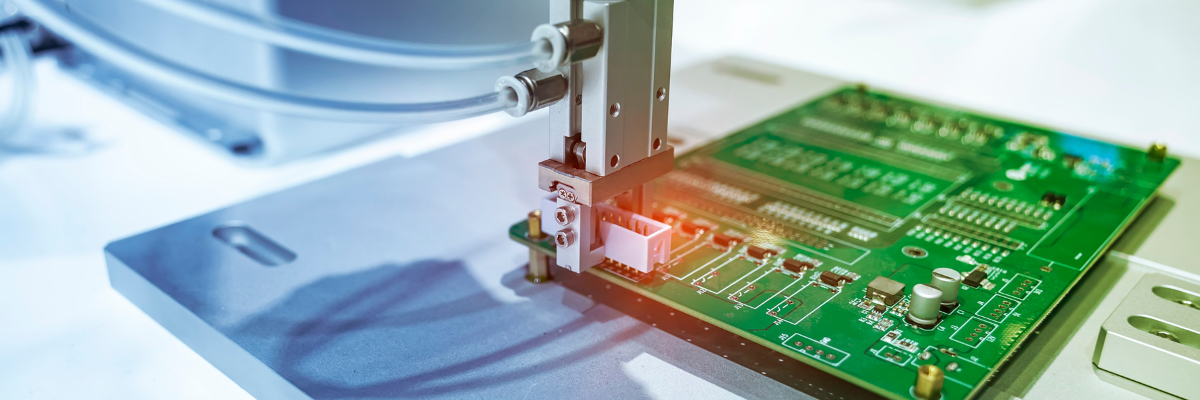

- PCB Assembly: Once the PCB has been fabricated, it needs to be assembled with the necessary components. The components are placed on the board using pick-and-place machines and then soldered in place using a reflow oven.

- Finishing: The final step of the PCB production process is finishing, which includes adding any additional components, coatings, or finishes to the board.

- Testing: After the PCB has been assembled, it is tested to check its functioning as per the customer requirements. This step involves using specialized equipment to check that the electrical connections are correct and that the board is working as intended

- Shipping: Once the PCB has been tested and approved, it is shipped to the customer.

Strict quality control measures are enforced through each of these phases to ensure the highest standards of production. By ensuring that each step is closely monitored and executed with precision, PCB assembly services specializing in fast turn PCB production can deliver a high-quality end product on time.

There are many more things you must know about before opting for fast turn PCB production, which will be discussed in the next post. Stay tuned.