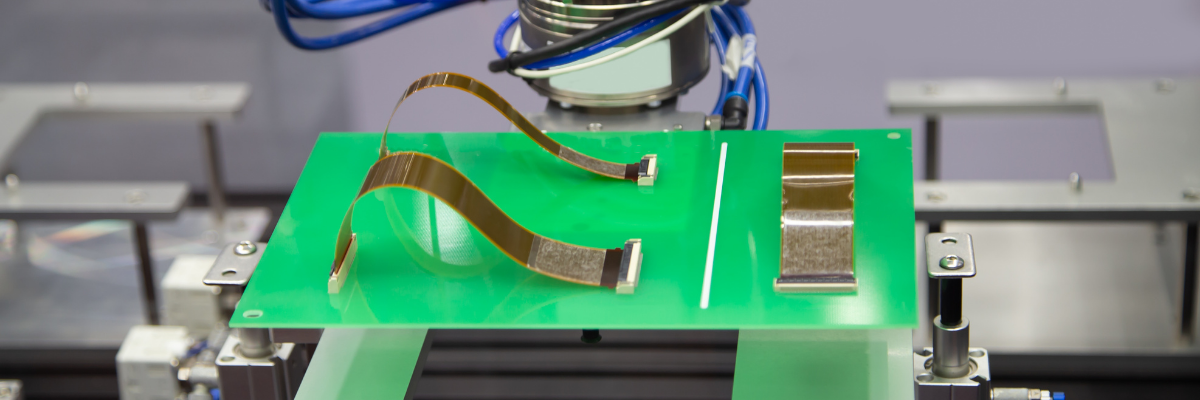

Flexible circuit boards are the solution for applications that require lightweight, small and thin printed circuit boards with high wiring density. The age of miniaturization requires flexible PCBs that can be three-dimensionally wired, and can be reshaped according to the applications and available space.

What is a Flexible PCB?

This type of PCB is made up of a flexible board with multiple wirings and connection pads conducted through wirings, provided on the edge of the flexible PCB. It is made by laminating the resin substrate with a copper foil; layers are joined with adhesive, or by applying heat or pressure to make an integral board.For proper insulation, adhesive layers, insulating layers, and encapsulating layers are placed between the conductive layers.

What are the different kinds of flexible circuit boards?

Following are the different kinds of flexible circuit boards used for varied electronic purposes:

Single sided flex circuit: It is one of the most basic types and is made of a flexible polyamide film laminated on a thin sheet of copper. The circuit pattern is made of etched copper layers according to specific design requirements. A polyamide cover is added to protect the PCB and to improve insulation.

Single sided flex circuit with dual access: It is a simply made single sided flex circuit with the conductive material that can be accessed from both sides of the circuit. Specialized laser and processing techniques facilitate dual access to the single copper layer.

Double sided flex circuits: This type consists of two conductive layers wherein requirement-specific trace patterns can be created on both sides of the substrate film. This can be connected with the help of copper-plated through holes.

Multi layer flex circuits: This type combines multiple single or double sided circuits with complex interconnections along with shielding and surface mounted technologies in a multi-layered design. It is an effective solution for unavoidable crossovers, elimination of crosstalk, specific impedance requirements, additional shielding, and high component density.

Knowing about the varied types of flexible circuit boards makes it easy and convenient for the customer to make the right choice, when it comes to attending an application with efficiency and accuracy.