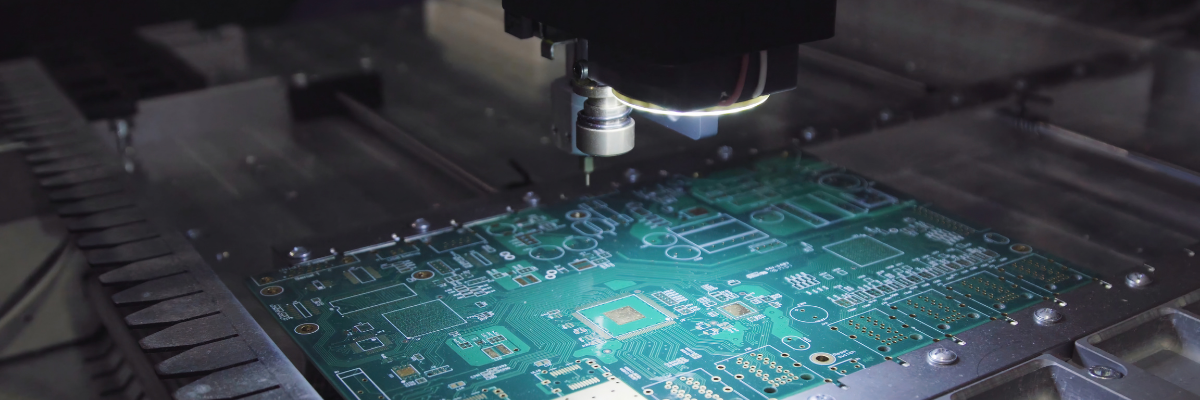

Printed circuit board assembly (PCBA) process is complex with multiple stages, which starts with designing, manufacturing, and testing of blank boards followed by the assembling steps. The rising demand for compact, performance-driven, and miniature devices has driven the growth of the PCB segment with complex designs and components. Today, most PCB assembly processes are automated. So, they can be produced in low volumes and bulk quantities as per the requirements. Low volume PCB production has gained immense traction and has become a preferred choice for many OEMs in specific situations. Are you intrigued to know more about what low volume PCB production is, where it is applicable and how does it benefit OEMs? If that sounds yes, this post is for you as it discusses important aspects and possible reasons of low volume PCB production. So, stay connected to know more.

What is Low Volume PCB Production?

The electronic components are mounted on a relatively small batch of bare boards, thus named low volume PCB assembly. There are approximately 250 or more circuit boards in one batch. Irrespective of the batch size – be it small or large- the board quality depends entirely on the synchronization of the design for manufacturing (DFM) and design for assembly (DFA) used by manufacturers. Low volume PCB assembly is mainly preferred for customized PCBs aside from many other reasons.

What Are the Benefits of Low Volume PCB Production?

Here is a list of low volume PCB benefits that have immensely contributed to their popularity. So, let’s take a quick look at it.

- One of the key benefits of low volume PCB production is the ability to quickly produce prototypes or small batches of PCB assemblies for further research, testing, and evaluation. This is especially important for companies developing new products, as it allows them to test their designs before committing to large production runs. By producing a small number of PCBs, companies can reduce costs and avoid the risk of producing large numbers of faulty or unusable products.

- Another benefit of low volume PCB production is the ability to create highly customized PCBs. Low volume PCB production allows for greater design flexibility and the creation of highly specialized or unique PCBs. This is especially important for products that require specialized features or functionalities, high precision, and zero tolerance for errors. These may include the ones used in medical devices, defense equipment, or heavy industrial equipment. Low volume PCB production also allows for greater design iteration, allowing companies to refine their designs and incorporate customer feedback into their products.

- Low volume PCBs allow manufacturers to make design changes and help them decide whether to proceed with the product or keep it on long production runs.

Nowadays, many PCB service providers waive off the stencil and non-recurring engineering (NRE) costs on repeat orders even in case of low volume production runs.

Low volume PCB production is one of the most critical areas that demands hands-on experience and immense knowledge. Despite several challenges, including cost and quality control, low volume PCB production offers many benefits. Today, you will find many PCB manufacturers and assembly service providers offering low volume PCB production. However, not all may deliver quality. Regardless of the circuit board design type and volume, it is essential to consult a reliable and trustworthy PCB assembly service provider. This is because PCB plays a vital role in the functioning of electronic devices. A small error may lead to an expensive repair. Rigiflex Technology stands tall among its other competitors. With years of market presence and skilled employees, the company provides low volume PCB assembly services, while it also has a high volume production and customization abilities.