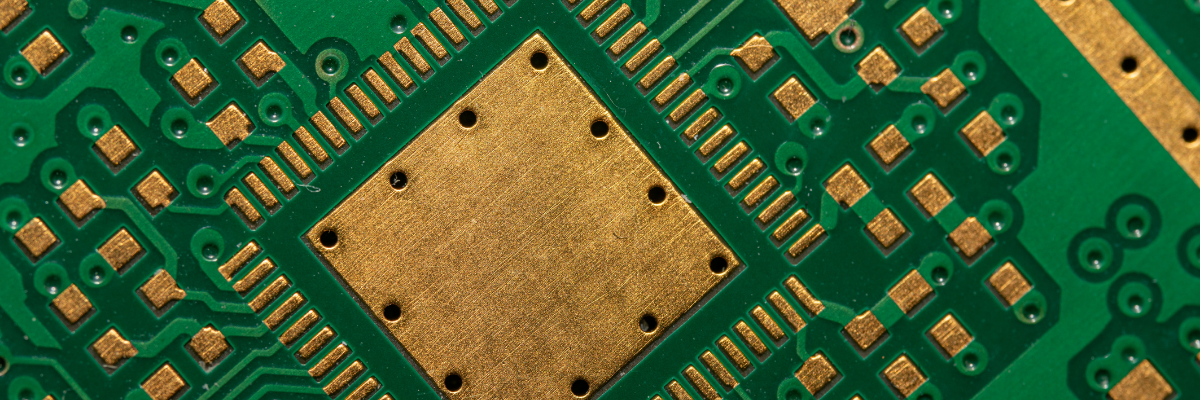

The Printed Circuit Boards (PCBs) are exposed to several environmental factors including dust, dirt, moisture, steam, high temperature, etc. All these circumstances may lead to the oxidation of the copper surface of the PCBs. To prevent the oxidation of copper, the PCB surfaces are coated with a thin layer of surface finish. There are multiple types of PCB surface finishes or coatings that are used in the PCB manufacturing process. However, the selection of PCB surface finish has to be compatible with external conditions. That is why this post discusses the importance of PCB surface finishes and a few guidelines to select an appropriate surface finish for application-centric PCBs.

Significance of PCB Surface Finishes

When it comes to the application of PCBs in a harsh environment, PCB surface finish becomes a highly important aspect. The PCB surface finish serves the following purposes in the security of PCB operation, and therefore, is of great significance.

- Prevention against Oxidation: The PCB surface finish prevents the copper surface from oxidation, which often occurs due to the interaction of copper molecules with the oxygen present in the air and moisture. The surface finish acts as the protective film against the oxidation of copper and the formation of a green layer.

- Prevention against Corrosion: Surface corrosion is one of the common challenges seen on PCB surfaces and metallic connections. The wire leads and surface often is susceptible to corrosion. The surface finish coating offers protection against rusting.

- Generating a Solderable Surface: The surface finish sets a base for soldering. On the surface finish coating, the components are mounted and soldered. In order to settle the solder paste properly, a correct surface finish should be chosen.

The surface finishes are typically applied when one or many of the following requirements are observed in a PCB fabrication process.

- High volume PCB production

- Need for reduction of shocks and electric drops

- Cost-sensitive PCBs application

- Fine pitch component mounting

However, if wire bonding is used in the PCB design and fabrication process then PCB surface coating is not recommended.

Selection Criteria for PCB Surface Finishes

When it comes to selecting a PCB surface finish, the consideration of the following factors can be beneficial.

- Operational Parameters of PCBs: The operational parameters like the number of layers, exposure of frequencies, resistance from high temperature, rust-proofing, etc, should be considered while choosing a surface finish. The surface finish material can be lead-based or lead-free and they may possess different compatibility with operational parameters of PCB. Therefore, this is an essential consideration.

- Different Types of PCB Surface Finishes: There are different types of PCB surface finishes. One can choose from one of the following PCB surface finishes.

- Hot Air Solder Leveling (HASL): It is a lead or tin-based surface finish. It offers an excellent surface finish, a wide window for soldering, and it is the least expensive surface finish.

- Lead-free Hot Air Solder Leveling: This is HASL but without lead. Being lead-free, this surface finish is RoHS-compliant.

- Organic Solderability Preservative (OSP): This is an organic surface finish that uses water-based cognatic solder material. It secures the copper surface before actual soldering. It also allows the application of an organometallic layer.

- Immersion Tin (ISn): It is a tin surface finish. A thin layer of tin is applied on PCB’s copper surface in this type. This surface finish is suitable for fine pitch components and ball grid arrays.

- Immersion Silver (IAg): It is a silver-based surface finish. It offers a lead-free, anti-tarnish surface that extends the shelf-life of PCBs up to 12 months.

- Electroless Nickel Immersion Gold (ENIG): This surface finish is achieved by layering the copper surface with nickel and gold. This surface finish is compliant with RoHS regulations. This surface finish offers several years of shelf-life to PCBs.

- Shelf-Life: The shelf-life is the duration for which the surface finished PCBs can be stored without tarnishing. Based on the scope of application, the shelf-life should be checked while choosing PCBs.