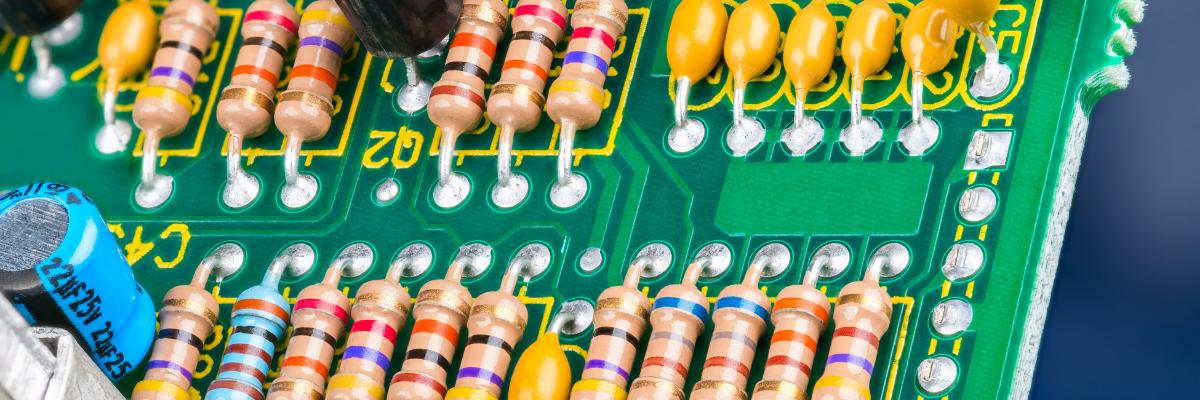

Printed circuit board recycling has become an important area within the PCB industry in the last few years. The reason for this is simple – printed circuit board are considered as hazardous waste, as they are manufactured with harsh chemicals and various materials that can harm the environment. Rather than adding to electronic waste, many organizations and manufacturers find it a better option to recycle PCBs.

Recycling PCB Copper

The essence of PCB recycling is to recover the metals in their pure metallic form. Copper is used in PCBs in a variety of ways. In this post, we shall be discussing the various processes used to recover copper materials from a PCB.

- Removing Copper from Edge Trims: The edge trim of PCBs consist of a plastic resin that contain large copper particles. The trim is shredded and ground to remove the plastic resin. A cyclone separator is then used to separate the copper metal particles from the plastic resin.

Another method is to use a stripping solution on the edge trim. This helps strip the copper, and it is removed as liquid form. The copper is then treated with reductants, which helps it regain its metal form. This method can also be performed for other precious metals in PCBs such as gold, platinum, and silver. - Recovering Copper Oxide from Wastewater Sludge: Many times, copper is discharged into the environment with wastewater sludge. Copper is in the form of hydroxide, and acts as a base for aqueous solutions like wastewater sludge. Before it can be recycled, the copper needs to be converted from hydroxide into copper oxide. This can be accomplished by heating the sludge to temperatures of about 600 to 750 °C. This helps remove the excess water and converts the copper into copper oxide. A smelter can then produce copper metal from the copper oxide.

- Removing Copper from Etching Solutions: In this method, the etching solution is treated to weaken its acidic state. This allows for the copper ions to be discharged from the solution in the form of copper hydroxide. A filtering process similar to sludge recycling is used to transform the hydroxide. The hydroxide can also be converted into copper sulfate. This is achieved by first dissolving the hydroxide in sulfuric acid. The copper is allowed to cool and crystallize. It then undergoes centrifugation and drying.

- Recovering Copper Sulfate from Plated Through Hole Process: In the PTH manufacturing process, used copper sulfate is present in the form of a liquid solution. It contains copper ions between 2-22 g/L. The spent sulfate solution is loaded into the reactor. The solution is disturbed while a chiller is used to reduce the temperature to 10-20°C. At this point, the copper sulfate crystal is removed from the solution. Centrifugation is then used to recover the copper sulfate crystal.

By using such methods, it is possible to save expensive materials, as well as reduce the carbon footprints of PCBs. In turn, this reduces the overall environmental impact. To know more about Printed Circuit Boards (PCBs) product offerings, log on to http://www.rigiflex.com/.