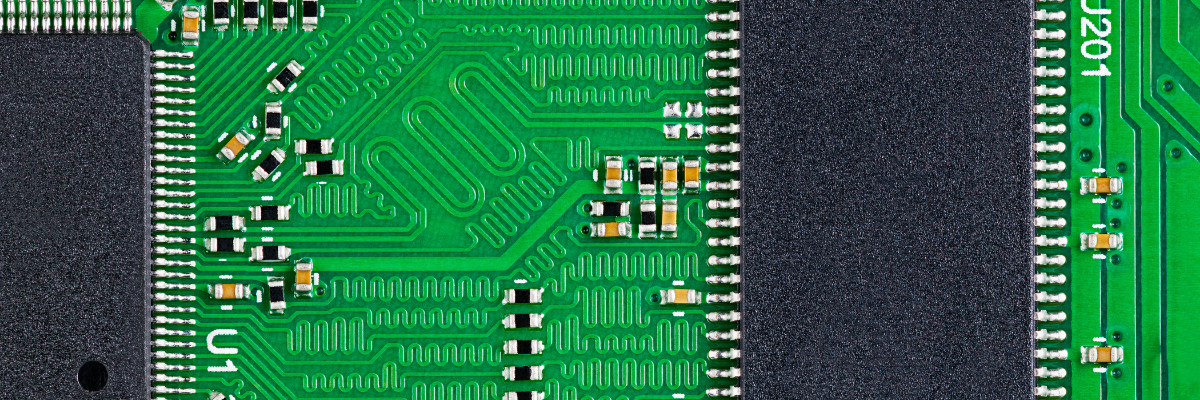

The printed circuit boards may look like small chips in big devices; however, designing, manufacturing, and assembling them require careful planning. The PCB assemblers use various types of implements when assembling these boards, and stencils are one of the important ones among them. This stencil is known as a surface mount technology stencil or a laser stencil which is used to assemble surface mount technology components. These stencils supply the solder paste to a naked circuit board in proper quantities for soldering surface mount devices or components. These PCB stencils have a significant contribution to manufacturing high-quality printed circuit boards to meet the market demands. Do you wish to learn more about SMT stencils.

How do SMT Stencils Work?

A PCB stencil is a thin pliable sheet generally made of aluminum or stainless steel. The stencil contains small apertures that form a design to be printed on a circuit board. Firstly, the stencil is positioned on a frame on the top of the circuit board. Then, the solder paste is applied evenly on the stencil. The solder paste passes through the apertures following their design which gets printed on a circuit board. The small holes control the quantity of passing solder paste, thus allowing an accurate soldering process on a PCB.

Types of SMT Stencils

Every PCB design is different, and so is the stencil’s type. Following are some of the most common types of surface mount technology stencils:

- Electroformed Stencils: Electroforming is a process that uses the deposition of an atom by atom to produce a stencil. This process enables produce highly accurate replicas from a master surface. An electroformed stencil is one of the best stencils that allow accurate solder pasting, and hence it is ideal for complex PCB soldering.

- Framed Stencils: As the name portrays, framed stencils are permanently fixed on a frame and are ideally used to manufacture high-volume printed circuit boards. As these stencils are fixed stencils, they offer accurate positional and dimensional application of the solder paste.

- Frameless Stencils: Unlike framed stencils, frameless stencils are not attached to a frame and are generally used for producing smaller amounts of printed circuit boards or prototypes.

- Prototype Stencils: Prototype stencils are used for manual applications in which solder paste is applied manually. These types of stencils are manufactured as per the data present in Gerber or CAD files. The best part about prototype stencils is that it helps eliminate printing mistakes in manual applications.

- Laser Cut Stencils: As the name suggests, these stencils possess apertures created using a laser machine. Laser stencils produce detailed and accurate designs that make them ideal for soldering complex printed circuit boards.

Benefits of Using SMT Stencils

PCB stencils add precision to the overall manufacturing of a printed circuit board. Some of the most notable benefits of using stencils are as follows:

- Stencils are cost-effective and can be used on a continuous repetition.

- Once used, stencils can be cleaned and used again with the same precision.

- Using the right stencil type can help eliminate issues like short circuits, disturbed pad position, burred side walls, voids during soldering, and so on.

- A PCB stencil allows the solder paste to pass only through the designed apertures and keeps the rest of the board’s part clean.

- Stencils ensure zero errors and flaws, whether used in an automated PCB assembly or manual process.

- Stencils save a lot of time while manufacturing PCBs in large numbers.

SMT stencils save time and add precision to the PCB assembly. Although these stencils may not be of much use for a layman or an OEM, they can partner with experience PCB services to leverage these stencils. Rigiflex Technology is one of the leading manufacturers of high-quality printed circuit boards. The company utilizes SMT stencils to improve the reliability of its printed circuit boards. In case you come across any queries regarding SMT stencils or any other services regarding PCBs, please do not hesitate to get in touch with the company.